New Zealand Phosphate Resources Could Supplement Imports

This project reveals greater deposits of phosphate than previously believed possible in New Zealand.

A widely-held belief that New Zealand imports the essential agricultural input phosphate from North Africa because the element doesn’t exist here naturally has been turned on its head. A new study shows the South Island’s east coast has the potential to contain phosphate deposits that could significantly supplement imported product.

The research project by The AgriBusiness Group and L&M Group undertook a fresh approach to the analysis of geological records derived from a wealth of geological studies and drilling data dating back many decades. They concluded that resources are potentially much larger than previous surveys revealed.

“It could not totally replace the need for imported phosphate based on the different raw material quality requirements. However, the scale of the resource would suggest there’s enough there to provide quite a large percentage of New Zealand’s phosphate needs for quite a long time in the future,” says The AgriBusiness Group director Jon Manhire.

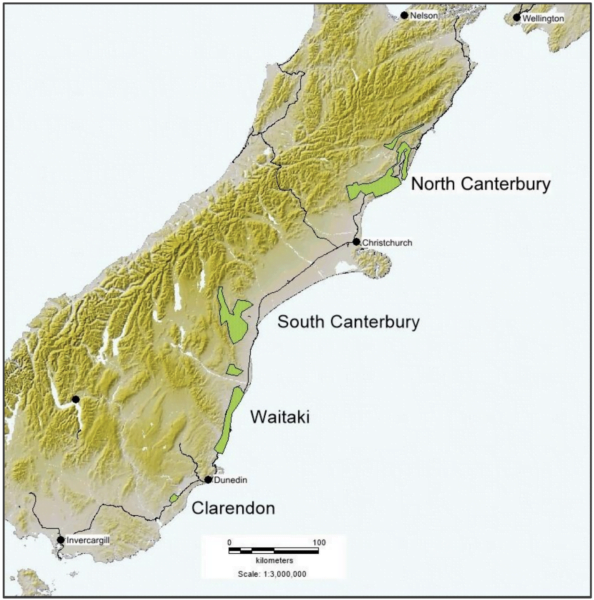

New Zealand’s largest known onshore phosphate deposits are at Clarendon, midway between Dunedin and Balclutha, and these have been mined intermittently since early last century (Map 1). Approximately 140,000 tonnes of phosphate rock were mined from there between 1902 and 1924.

When Japan captured the Pacific island of Nauru (the main source of phosphate for New Zealand farmers) in WWII mining was resumed at Clarendon, with around 30,000 tonnes taken between 1943 and 1955. The mine was abandoned again when supplies from Nauru resumed.

Today the only sign there was ever a phosphate industry in the region is the long disused Ewing Phosphate Company building on SH1, just north of Milton, something of a local landmark.

While the extent of the resources is not widely known today, as recently as 2008 Ravensdown took another look at the Clarendon area.

“The team at Ravensdown have been very generous with their time and advice and have shared information with us. At the time they decided not to go further with it,” says Manhire. “But since then much has changed, for both the science and in global politics.”

Sustainable phosphate future

Why: To analyse the quality and environmental impact of sourcing phosphate from onshore deposits in New Zealand.

Where: Sites in Otago and Canterbury were analysed via geological data, modelling, mapping and sampling.

Who: Stuart Ford, Ann Moriarty, Jon Manhire (The AgriBusiness Group) and David Manhire (L&M Group).

What:

- Five regions were identified that warrant detailed evaluation for phosphate deposits. The combined North Canterbury and Kaikoura areas have the potential to contain 10-20 million tonnes of phosphate.

- New Zealand phosphate could be competitive with imported products.

- There would be relatively minor environmental effects from the quarrying process.

Phosphate supply issues

“Phosphate was originally surveyed in the early 1900s, so the science of geology has moved on a

bit. The whole issue around security of supply has become a lot more questionable,” Manhire says, referring to international tension around the politics of the phosphate supplied by Morocco.

While the Moroccan resource is vast, capable of supplying New Zealand’s needs for hundreds of years, other sources of supply (like China where 10% of our phosphate used to come from) have now closed. That makes New Zealand vulnerable to any interruption to shipments from North Africa.

“To be honest, we’d be screwed,” says Manhire. “Phosphate is an essential element for pastoral production and without it your productivity is depressed. There could be options to bring it in from Australia, but those resources aren’t that well developed and if New Zealand has phosphate in our back door, why not use our stuff? I think these strategic issues around mineral use and availability are becoming quite important.”

L&M Group has been investigating phosphate resources for mining potential in New Zealand for several years. Their analysis led to the development of revised geological models that suggest the size and quality of the local onshore resource is bigger than had previously been believed.

While Clarendon is the only location where there has been detailed exploration and mining for phosphate, L&M Group also has prospecting permits for deposits further up the east coast of the South Island at Waitaki, South Canterbury, North Canterbury and Kaikoura (Figure 1).

Building on these initial investigations by L&M Group, five regions were identified that may warrant detailed evaluation. Criteria for selection were primarily the potential size and grade of the deposit, and secondarily, the location in relation to transport and infrastructure.

L&M Group has calculated that based on the ore thickness and grades indicated by drilling, the deposits have the potential to contain significantly more resource than that indicated by the areas drilled to date.

The combined North Canterbury and Kaikoura exploration permit areas have the potential to contain 10-20 million tonnes (Mt) of phosphate resources. Depending on grade and beneficiation efficiency, the total could be considerably higher.

There is insufficient data available to assess the Waitaki and South Canterbury resources, but given the extent of the target formations there is potential for multi-million tonne deposits.

Environmental benefits and risks

One potential advantage of New Zealand phosphate is that it contains less cadmium than imported supplies.

“We used to get a lot of phosphate from Nauru and that had very high cadmium levels,” explains Manhire. “We ended up with quite a large problem in New Zealand of cadmium soil contamination. Cadmium bio-accumulates in kidneys of sheep and you can’t buy adult sheep kidneys in New Zealand because of the cadmium loading.”

New Zealand resources generally contain lower levels of phosphate than imported supplies.

“We can lift it to very close to that level but that adds cost to it. There are also uses for the lower grades as well that haven’t been that well investigated,” he says.

As well as supplementing the raw material used to produce soluble superphosphate, the local product could be used in other forms of the fertiliser, including Reactive Rock Phosphate (RPR) and Partially Acidulated Phosphate Rock (PAPR).

“These products have lower solubility so the risk to water pollution is significantly lower, and there can be a win-win there in terms of achieving environmental gains as well as decreasing the cost of inputs,” says Manhire.

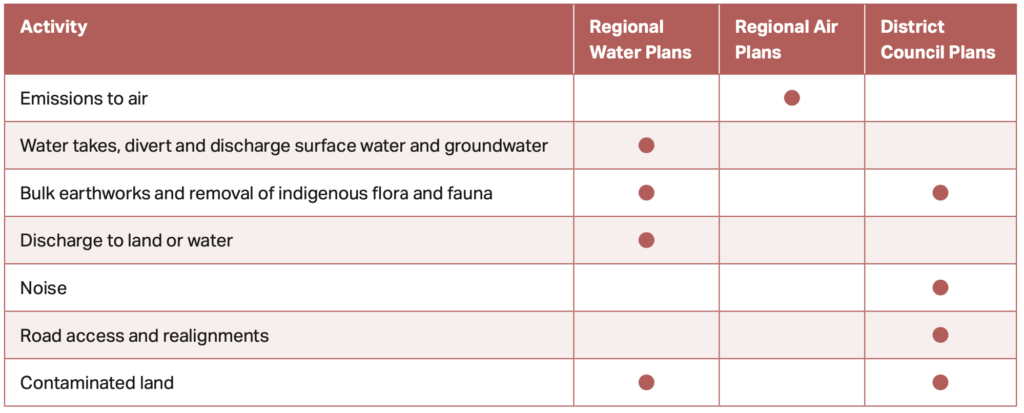

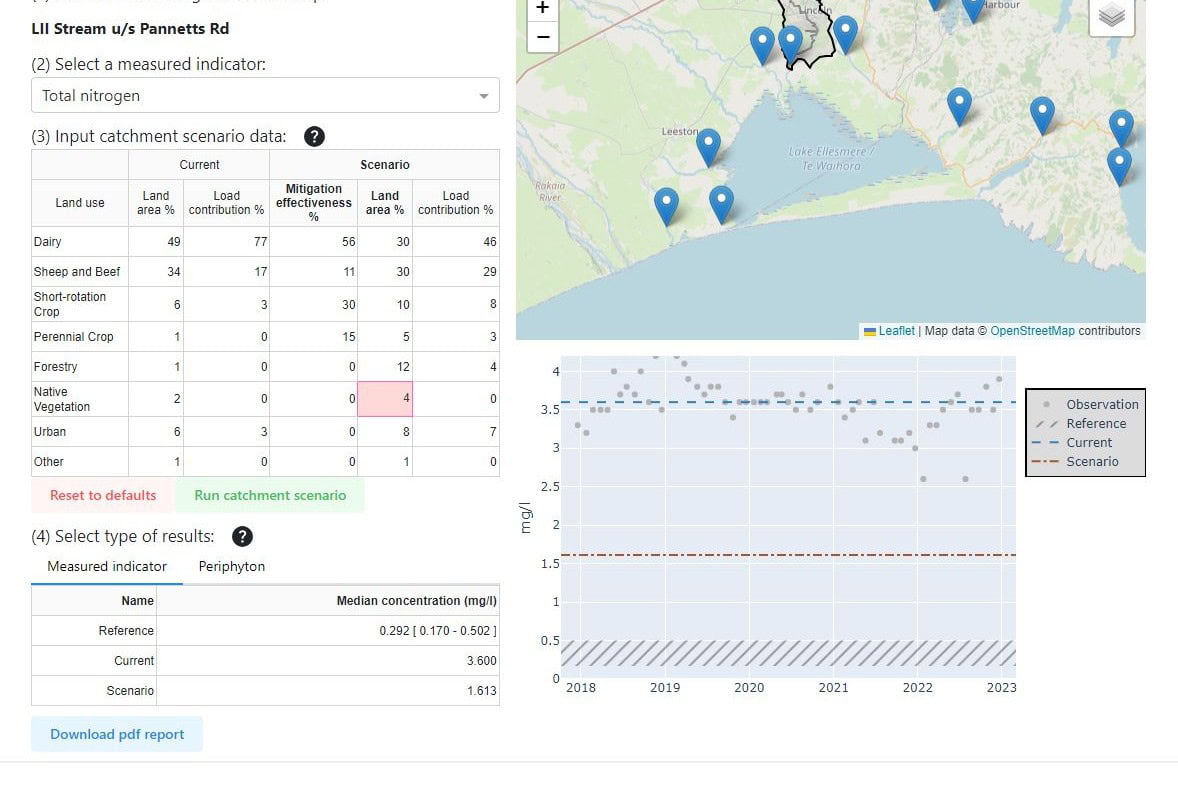

The project’s report concludes there would be relatively minor environmental effects from quarrying (Table 1), like those for limestone (Figure 2).

Another potential environmental gain for locally sourced phosphate is that if it was used to produce Single Super Phosphate (SSP) in place of imported raw material, its carbon footprint would drop by more than half. This result is largely due to the much shorter transport routes.

“A comparative analysis of the carbon footprint from imported and New Zealand sourced phosphate for the production of SSP indicate that the GHG emissions from the New Zealand source phosphate rock is 76 tonnes of CO2 per tonne of SSP, which is 49% of that of the imported material,” says Manhire.

New Zealand resources generally contain lower levels of phosphate than imported supplies.

The AgriBusiness Group also analysed projected costs of mining and processing the resource, but noted that this was light on detail because of the limited available data. Although this analysis suggested the deposits could be mined, without additional data there remains questions over whether the deposits are economically viable compared to imported phosphate ore.

“Based on the work carried out so far, the indications are that there are some quite big resources there and I think some of the geological models that L&M have applied to the resource suggest that it’s a lot bigger than was originally looked at,” he says.

Most New Zealanders don’t know about our phosphate resources – even farmers whose land has the mineral beneath the surface.

“It might be a surprise to people that we’ve got it here. In fact, I know from L&M, when they’ve been going onto farmers’ land they just didn’t have any clue. We know a lot about the resource down in Otago, we’ve got some pretty good data on that, but for the other ones I think there needs to be a little bit more done.”

Most New Zealanders don’t know about our phosphate resources – even farmers whose land has the mineral beneath the surface.

The report contains a strategic analysis relating to the use of New Zealand phosphate and identifies a range of economic, environmental and social benefits with comparatively few weaknesses. The use of New Zealand sourced phosphate for fertiliser appears to be viable and feasible, while providing potential economic and environmental benefits.

Suggested follow-up actions include a more detailed analysis of the environmental and economic

impact of using New Zealand phosphate resources and an increase in farmer awareness of the advantages of using alternative (and less soluble) phosphate fertilisers.

Manhire says many countries list the strategic elements in their territory and try to protect them, and he believes New Zealand should do the same thing with phosphate.

“The EU and Australia have phosphate really high up there. New Zealand is in the process of developing a list so hopefully our report will highlight the need to have phosphate on that list,” he says.

This article was first published in New Ground magazine, issue 4. All text is licensed for re-use under Creative Commons Attribution 4.0 International (CC BY 4.0)

Author

View Our Strategy Document 2019 – 2024

View Our Strategy Document 2019 – 2024

Leave a Reply