Daffodils Could be a New Crop on South Island Sheep Farms

Daffodils grown to produce galanthamine, an active ingredient in medication to treat Alzheimer’s disease symptoms, have been successfully trialled on South Island sheep farms.

Many families have gone through the heartbreak of watching a loved one slowly succumb to Alzheimer’s disease. Despite billions being poured into the dementia drugs market for research and development over the last 20 years, there are still relatively few drug options available to treat the growing number of people who live with dementia, of which Alzheimer’s disease is the most common type.

Though not a cure, one drug on the market shown to slow Alzheimer’s progress and reduce symptoms (including memory loss) comes from galanthamine, an alkaloid substance found in some plants. There are high levels in some daffodils.

Daffodils are the favoured source for commercial extraction of galanthamine by UK-based Agroceutical Products who are behind large-scale daffodil production already underway in Wales. They were looking for a southern hemisphere source to enable year-round production.

While found in many plants, other sources of galanthamine tend to have lower levels, with the plants killed at harvest. Daffodils, on the other hand, are a no-fuss perennial and can be harvested for years.

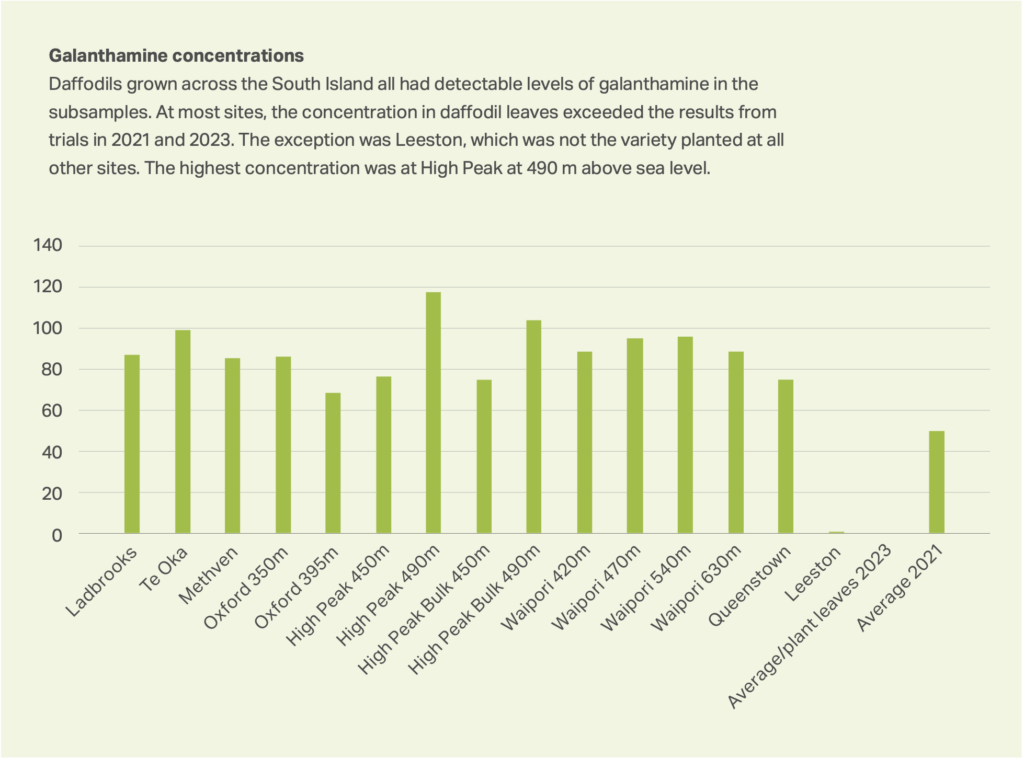

It’s thought daffodils produce higher concentrations of the compound when stressed, including through poorer soil, challenging climates and higher altitudes. Sheep’s aversion to eating them, while grazing around them, makes daffodils easy to integrate into existing high country farming operations. Such an operation would potentially add a new diverse revenue stream for farmers on poorer soils.

Though not a cure, one drug on the market shown to slow Alzheimer’s progress and reduce symptoms comes from galanthamine, an alkaloid substance found in some plants.

Nick Pyke, crop technologist and director of sustainable arable farming consultancy Leftfield Innovation, approached Our Land and Water for funding through the Rural Professionals Fund to carry out growing trials. The team at Leftfield is looking to find a way to multiply the bulbs quickly for the big numbers that would be needed for commercial production.

Trial plantings got underway in seven South Island sites in autumn 2023 (Figure 1), to see how the daffodils fared in different environments and if they would produce high enough concentrations of galanthamine.

Seven sites in the South Island were trialled, from coastal and almost at sea level on Banks Peninsula, to 630 m above sea level in Otago. Soil pH and fertility (Olsen P) were recorded for each site.

Plots of one square metre with a minimum of 100 bulbs were planted on each site. Larger 10 square metre plots were also set up on several properties, with rows of bulbs at 70 cm apart to simulate commercial planting. A 10 square metre site at Methven was planted with the higher density of at least 100 bulbs per square metre for a comparison in yield potential.

Four months later, 10 plants from each site were removed, along with separate bunches of leaves, and tested for galanthamine. The use of High Performance Liquid Chromatography (HPLC) enabled the team to gauge and compare how many milligrams of galanthamine per plant were being produced across the different sites.

Daffodil production for galanthamine

Why: Galanthamine extract to treat symptoms of Alzheimer’s disease could create a new income stream for sheep farmers in hill country, with little management change needed to current operations.

Where: Seven sites across the South Island, with a range of altitudes, soil fertility and environments (including a coastal site) from sea level to 630 m above sea level.

Who: Nick Pyke (Leftfield Innovation), Kevin Stephens (Agroceutical Products), Michaela McLeod (AgEvaluate), and Travis Glare and Josefina Narciso (Lincoln University).

What:

- Commercial concentrations of galanthamine were produced on all the daffodil sites.

- Stress may produce higher levels of galanthamine in daffodils, but altitude, soil pH or phosphate levels weren’t shown to be stressors.

- Micropropagation of bulb tissue to produce the high numbers of bulbs needed for commercial planting was shown to be achievable, but it needs more refinement.

Surprising results

Concentrations of galanthamine varied in each plant across the various sites, as did the size of the plants. While the plants grew bigger at some sites, there was little correlation between plant wet weight and the concentration of galanthamine. There was also no relationship between soil pH or phosphate levels. Nor was there a trend with elevation, which is contrary to the current understanding from Welsh production.

Dry matter (DM) produced from the high-density plantings at Methven was significantly more at nearly 3,000 kg of DM/ha, compared to the yields of 622 kg/DM/ha at the Oxford site and 382 kg/DM/ha at High Peak Station near Darfield.

Because of the wide variation in galanthamine levels across the sites, the team weren’t confident about estimating an exact weight of galanthamine that would be produced per kilogram of DM.

“Production levels vary at different sites as the growth of the plant and galanthamine levels are not strongly correlated, so any figure is just a guide,” says Travis Glare, research director with Lincoln University.

The team estimates between 310 g and 440 g of galanthamine could be extracted from a hectare of DM.

During their annual hibernation daffodils store energy from the current growing season in the bulb to spur on growth in the next season. These stored metabolites may have offset some of the effects of a harsher environment and different nutritional levels the plants experienced during the trial, potentially affecting the amount of galanthamine they produced.

Any carry-over influence the previous season’s environment has on galanthamine levels should become clearer this coming season. Allowing the daffodils to settle in over a couple of seasons on the sites will also likely give a clearer picture of how stressors, including altitude, affect galanthamine levels (Figure 2).

Micropropagation process tested

Also getting underway in autumn 2023 and lasting six months was work at Lincoln University to nail down a cost-effective way to multiply bulb tissue in a laboratory – similar to pine production. The daffodil bulbs used weren’t the same as those in the trials, coming instead from a commercial garden nursery with their variety unknown.

Propagation wasn’t as straightforward as hoped, with early issues over fungal contamination resulting in poor regeneration. The process was then tweaked to single rather than multiple baby plants grown in a commercial plant growth medium. This resulted in less fungal issues and better regeneration.

Also getting underway in autumn 2023 and lasting six months was work at Lincoln University to nail down a cost-effective way to multiply bulb tissue in a laboratory – similar to pine production.

After three months the healthy regenerative tissue was then grown on in fresh growing mediums with varying amounts of root initiator and sucrose, producing 18 regenerant plants. While not a large number of plants, the team are confident the process can be further refined, making micropropagation an option to produce the large number of bulbs needed.

Following on from the trials, an entity will now be formed to develop a business plan along with more research and development in New Zealand, says Nick Pyke. A business model that delivers the value directly back to the farmers, as much as possible, will be part of this process.

This article was first published in New Ground magazine, issue 4. All text is licensed for re-use under Creative Commons Attribution 4.0 International (CC BY 4.0)

Author

View Our Strategy Document 2019 – 2024

View Our Strategy Document 2019 – 2024

Leave a Reply