Wheat Shows Promise in North Island

Despite record-breaking rain, two North Island sites growing milling wheat showed good yields and quality could be achieved in a normal season, but it was not possible to investigate the effectiveness of spring-sown wheat in scavenging nitrogen.

“Growing milling wheat in the North Island, closer to New Zealand’s major domestic markets, is a realistic option,” says Wairarapa farmer Mick Williams, following a research trial on his property last summer.

“We were already growing a little bit of feed wheat, but the milling wheat ticks a few boxes in terms of feeding people rather than animals,” he says.

“We obviously want the financial rewards too, and that’s the idea of being involved in a project, to gather information that we can take to the consumer and say, ‘This is why you should be using New Zealand wheat, particularly North Island wheat’.”

The trial, conducted on two North Island farms, has shown there is potential to profitably grow milling wheat closer to major markets. This mitigates the prohibitive cost of shipping grain from the South Island, as well as showing that growing wheat can be an effective N mitigation technique.

Despite a summer of extreme rainfall that severely impacted yields and quality milling wheat, the researchers believe the cultivar field trials in Wairarapa and Ohakune showed growing wheat in a normal weather year could be a valid option.

While most New Zealand wheat is grown in the South Island, more of our population live in the North, and it’s often cheaper to import wheat from Australia than ship it across Cook Strait.

“If we could grow enough high-quality milling wheat in the North Island, that would potentially reduce the reliance and reduce the risks associated with food security bringing wheat in from wherever in the world,” says Nick Pyke of Leftfield Innovation, one of the research partners, along with The AgriBusiness Group and Forages NZ.

North Island farmers have other potentially more profitable options (for example, vegetables or fruit in Hawke’s Bay), but Pyke sees a role for wheat too.

“The opportunity for wheat is that it can fit into a range of farm systems to utilise the N that is potentially available from the other farm system and reduce the risk of leaching. If it was fitted into a dairy farm system it could potentially reduce greenhouse gas emissions – but the issue is, is it viable?” he says.

Spring milling wheat as a nitrogen scavenger in the North Island

Why: To investigate whether milling wheat can be profitably grown in the North Island to replace imported wheat, and how effectively the crop scavenges nitrogen (N) reserves in the soil, thereby reducing the risk of N leaching.

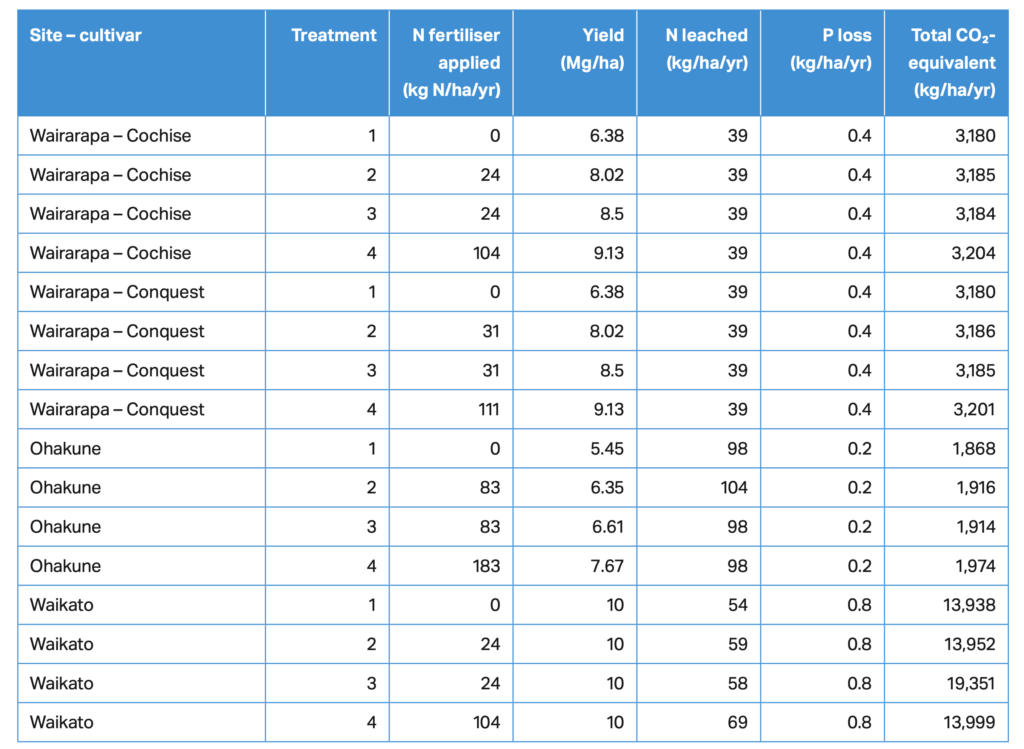

Where: On two properties in Ohakune and Wairarapa, and a virtual modelled Waikato dairy farm.

Who: Nick Pyke (Leftfield Innovation Ltd), Julie Lambie and Stuart Ford (The AgriBusiness Group) and Michaela Mcleod (Forages NZ).

What:

- Extreme rainfall throughout the growing season at both sites meant it was not a suitable season to investigate how effective spring- sown wheat was in scavenging N.

- In the Wairarapa, yield increased as applied N increased, or as N became available after GS32 (the growth stage where a second node is detectable), but was lower than forecast.

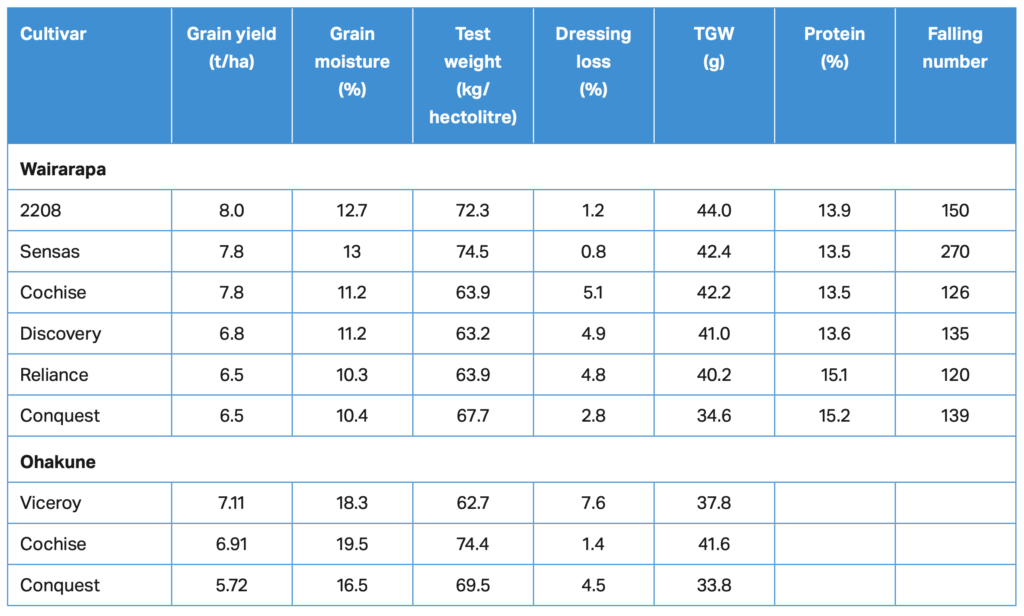

- A concurrent cultivar trial in the Wairarapa produced reasonable yields of milling wheat. Given the season’s conditions the quality was very good, indicating milling wheat could be a valuable land use diversification.

- In Ohakune, yield increased as applied N increased, but was significantly lower than forecast and lower than in previous years. The soil N plus applied N was adequate.

- For Wairarapa and Ohakune, there was little difference in modelled N or phosphorus (P) loss between any of the treatments.

- For GHG emissions, there was a small increase in nitrous oxide and carbon dioxide emissions associated with fertiliser application.

More:

The research team looked at regions that would normally have climatic conditions suited to growing wheat and identified Ohakune, in the rain shadow of the Kamai Range, and Wairarapa.

The trial’s objectives at the two sites were to assess milling wheat cultivars for their grain yield and milling characteristics to determine whether wheat of milling quality can be produced in each region.

The trial also aimed to understand N uptake from the soil by the wheat crop, by conducting deep soil N tests before sowing, after sowing, and after harvest, and applying N at different rates and timings.

On the Wairarapa site, Conquest wheat was direct drilled ex-rape and plantain for the N-replicated plot trial work. Another paddock was sown for cultivar evaluation.

At Ohakune, one large paddock was identified for the N-replicated plot trial work, and the cultivar evaluation was done in the remainder of the paddock. The paddock was ex-pasture and establishment was following minimum cultivation.

As well as the field trials, N and P loss and greenhouse gas losses were modelled using OverseerFM for four treatments:

- Soil N only

- Soil N + urea at planting (N to deliver 15 kgN/t wheat)

- Soil N + urea at growth stage 32 (N to deliver 15 kg N/t wheat)

- Soil N + urea at growth stage 32 (N to deliver 25 kg N/t wheat).

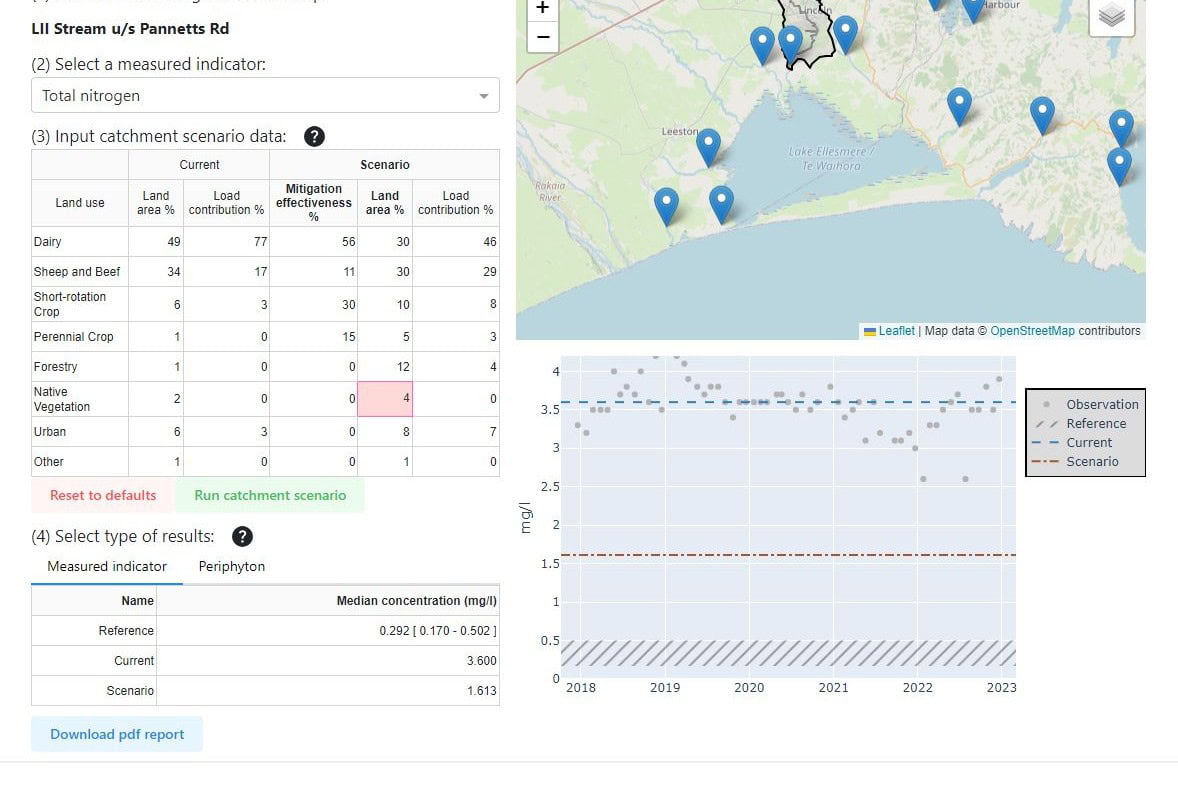

A Waikato dairy farm was modelled, based on a dairy unit in Morrinsville to represent a farm system in the area.

“We modelled with OverseerFM to ensure that the practices we were using in the field could be effectively modelled, and the field and modelled results were comparable,” says Pyke.

For Wairarapa and Ohakune, there was no difference in modelled N or P loss between any of the treatments at either the block or whole farm level. In the Waikato, the highest modelled N loss was for a treatment with N applied at GS32 and the N was not used to generate yield (see Table 1).

For GHG emissions, there was a small increase in nitrous oxide and carbon dioxide emissions associated with fertiliser application.

Rain-impacted nitrogen tests

While the sites were chosen because they had the right climate to grow wheat, conditions were testing from the start of the trial. The 503 mm of rain in the Wairarapa during the growing season was 188 mm above the 10-year average, and the 954 mm of rain in Ohakune was 390 mm above the 20-year mean.

The unusually rainy season meant it was very difficult to interpret the nitrogen (N) results with any confidence. These weather conditions could have had three unplanned impacts on N use:

- Reduced N uptake to grain due to lower yields than forecast.

- Reduced N uptake after application at planting due to N leaching below the root zone of the developing plant.

- Greater leaching and loss of more N from the lower profile.

As a result, it was not a suitable season to investigate how effective spring-sown wheat was in scavenging N, one of the project’s objectives.

The falling number is a measure of alpha-amylase activity in wheat that indicates the ability for bread made from it to rise. It is strongly affected by rain at harvest time.

“The rain not only delayed harvest but caused that falling number to drop through the floor,” says Pyke.

The falling numbers were representative of the very wet season and harvest and were very low in the Wairarapa and reasonable in Ohakune. Visible sprout was evident at both sites.

Despite the wet season, the Wairarapa site did produce reasonable yields of milling wheat.

“The yield in Ohakune was about half of what they got the year before. In the Wairarapa we got two- thirds the previous yield, so that was disappointing – but encouraging given they never really saw the sun at either place,” says Pyke. “The quality, with the exception of falling number, was very good, indicating milling wheat could be a valuable land use diversification.”

He also says that in normal conditions a wheat rotation could rank favourably against most N mitigation techniques because it is a technique that has very little cost.

Despite a season “where it rained and rained and rained”, the trial did provide encouraging results.

“I know we can grow a good crop of wheat and get decent yields, it’s not that difficult. It’s how we grow it to get the quality we need and utilise the nitrogen available in the system that’s the challenge,” says Pyke. “At the end of the day, it looks like there’s significant potential.”

Despite the terrible conditions over the season, farmer Mick Williams has seen enough to convince him to grow milling wheat again. “We definitely want to carry on with it. We’ll still do a bit of both feed and milling wheat, but the milling wheat interests me more, trying different varieties and hopefully making a connection with the end user. It’d be nice to able to go in and see bread that we know was made with our flour.”

This article was first published in New Ground magazine, issue 3. All text is licensed for re-use under Creative Commons Attribution 4.0 International (CC BY 4.0)

Author

View Our Strategy Document 2019 – 2024

View Our Strategy Document 2019 – 2024

Leave a Reply