Mooving in on the Soggy West Coast

On the West Coast, where annual rainfall is measured in metres, life has been cosy for dairy cows and staff in new composting shelters, especially during cold wet weather.

Aside from the remoteness of where they farm, some of the biggest challenges for West Coast dairy farmers in the South Island are around winter management and the sheer volume of rain they receive.

“The conundrum with winter grazing is, do you winter cows on freer-draining soils and risk increasing nitrate loss, or go to heavier soils where you could have issues with pugging?” says farm consultant Harry Millar.

“Heavy rainfall means there are probably fewer options on the coast,” he says. “This is especially true when considering where policy settings are heading and the focus on intensive winter grazing.”

Composting shelters, or ‘mootels’, are now another option. Mootels see cows housed off-paddock over winter and fed supplements undercover, with urine and dung absorbed into bedding material for compost.

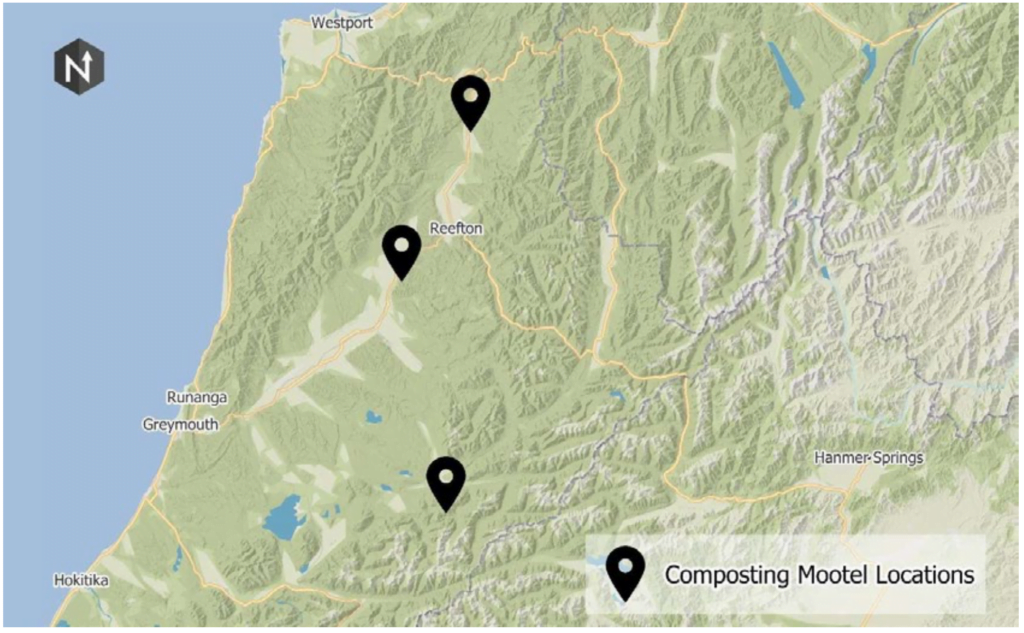

After observing West Coast farmers erecting composting mootels (see Map 1), farm consultant Robb Macbeth of Peak Agricultural Consultants, along with Josh Brown and Harry Millar of Rural Consulting, applied for funding from Our Land and Water’s Rural Professionals Fund. They sought the funding to assess the farmers’ key considerations, particularly for structure design and compost management in their wet environment.

Composting mootels on the West Coast

Why: To compare different composting shelter (or ‘mootel’) structure designs, and best practice for compost maintenance, in challenging wet conditions.

Where: Three dairy farms with recently constructed mootels on the West Coast.

Who: Robb Macbeth (Peak Agricultural Consultants), Josh Brown and Harry Millar (Rural Consulting), Keith Woodford (Agri-Food Systems), Gaye and Murray Coates (Prospect Farm), Carmel and Matt O’Regan (Mangawaro Farm), and Wendy and Tegel Oats (Turkey Creek Farm).

What:

- OverseerFM modelling and pre- and post-mootel integration for Prospect and Mangawaro Farms indicated an average nitrogen (N) root zone loss reduction of 47% (Turkey Creek Farm was lower, at 18.2%).

- Cows in mootels were more efficient at feed conversion. Utilisation also increased. As a result, the need for intensive winter grazing was reduced.

- Farmers observed anecdotal evidence for improvements in cow and staff wellbeing through reduced exposure to winter weather and soft, dry bedding for the cows.

- Mootel construction ranged from $1.2 to $2.9 million. Noting inflation, prospective mootel farmers should consider a range of $3,500 to $6,000 per cow, plus annual woodchip bedding of 3 m3 per cow at $25 to $35/m3.

More:

ourlandandwater.nz/outputs/west-coast-mootels

ourlandandwater.nz/outputs/composting-mootels-summary

Farmer motivation

The welfare of their cattle during winter was behind the farmers looking into mootels, with other factors including regulatory pressure, future business sustainability and potential staff benefits.

“The composting process would provide fertiliser, but the compost soon became as much about cow comfort as about nutrients for pasture,” says Millar.

The farmers felt incorporating mootels into their farm systems would help ease social licence concerns and regulation around winter grazing, while lifting milk production and profit.

The farmers had visited several farms with different structures available, talked to current users of composting shelters, and checked local council consenting requirements. Seeing a cow slip on a concrete floor in a different shelter type clinched the soft-floored composting mootel decision for one farmer.

Structure design

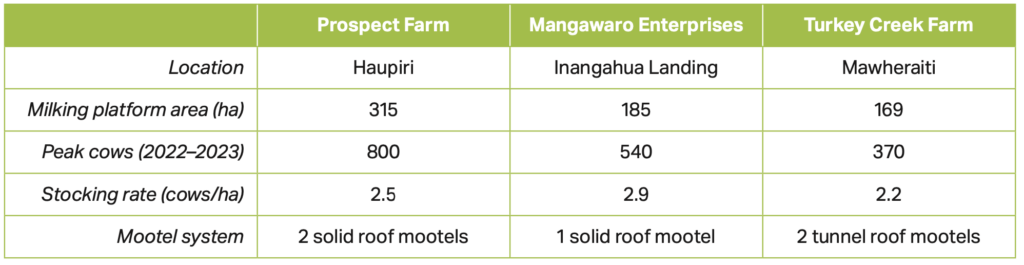

Two of the West Coast mootel case studies had solid roofs, and a third with a translucent plastic tunnel- roof mootel came on board a little later in the project (see Table 1). All the structures were positioned to take advantage of prevailing winds.

Mootel construction costs ranged from $1.2 million to $2.9 million – around $3,200 to $4,000 per cow – and included site work, concrete, bedding, and plant and equipment. Costs have since increased due to inflation. Depending on the farm, an increase in milk production of 11%–16% was needed to break even on the investment, says Macbeth.

High moisture content from urine and dung leads to lower temperatures in bedding, and can slow down the composting process. Should composting stop, the bedding becomes anaerobic and starts to rot. Good airflow is needed to help moisture evaporate and keep compost temperatures high.

Good water collection off the roof and drainage is important to keep water out and feed dry. The two mootels with solid roofs had an 18-degree roof pitch with ridge venting. Both ends of the tunnel shelter were fully open.

The two solid-roof mootels had two five-metre-wide concrete feeding lanes for vehicles inside the structures, while the tunnel shelters had external feed bins along the sides of the structure.

Not connected to the farm effluent systems, bedding absorbed the manure and urine. While the mootels had sub-surface drainage as a precaution, no drainage was seen during the study.

Bedding management

Pinus radiata woodchip was used for bedding on all three farms as it broke down slower than materials like sawdust or straw.

Chipping on-site was seen as a cheaper option by two farmers, while also being able to dictate chip size and with the contractor able to cart it into the shelter. One cubic metre of log gave between 2.4–3 m3 of chip. Between 5.2–7 m3 of material per cow was used initially to fill the shelters, with a top-up during the year of around 3–4 m3 per cow.

Forestry material from a hectare of on-farm mature radiata pine was estimated as enough to supply bedding material for between 400 to 550 cows annually. Storing logs for at least a year to dry out before for chipping is a possibility, with composting temperatures rising when this drier chip was added during the year.

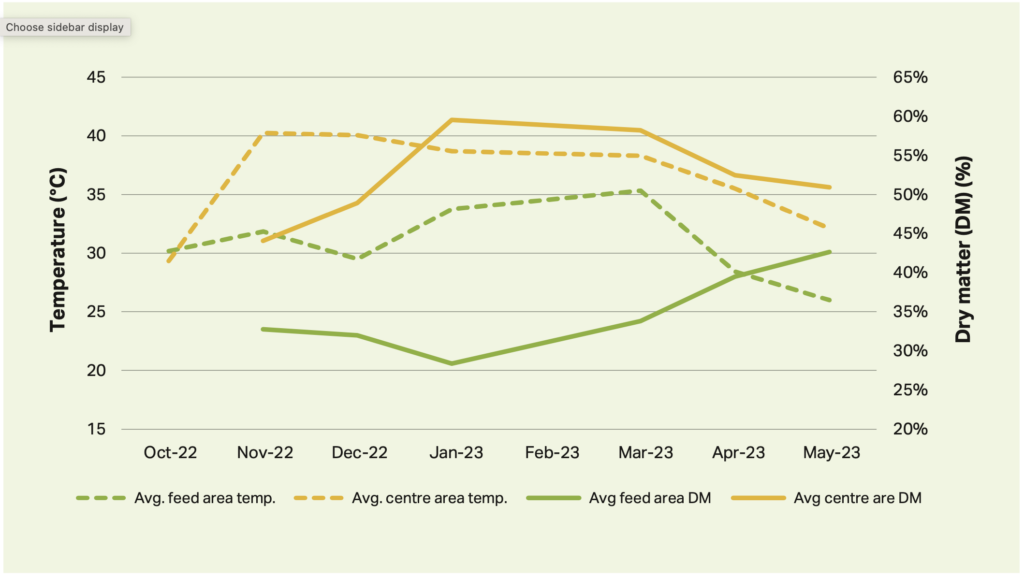

Bedding temperature samples were taken for the mootels between October 2022 and May 2023 at depths of 200 mm, 300 mm (see Figure 1) and 400 mm.

Recommended compost temperatures of between 50– 60°C at a depth of 15–30 cm weren’t being reached in the solid-roof mootels, although the composting process was still taking place. Lower temperatures, more moisture and some anaerobic composting were seen next to the feed lanes, where cows urinated and defecated more while eating.

The tunnel house compost reached these higher temperatures at times, with less clumping next to the feeding lanes. A stocking rate of 9.3 m of space per cow in the tunnel house compared to 6.5 m and 7.4 m in the others may be behind this, and possibly muted light through the plastic roofing. Skylights are now being considered by one farmer.

More frequent and deeper tilling, and adding more material, were tried. Scrapping was also used by one farmer. Concreting this strip was considered a possibility, or feeding in an area separate to the mootel connected to the farm effluent system.

To reduce the moisture content in winter, palm kernel extract or feed concentrate were considered, along with growing maize for lower moisture silage instead of pasture silage.

Tilling frequency varied, and more tilling may help reduce moisture. When cattle were in the shelters full-time, tilling was at least once a day. If the shelters were only used for a couple of hours a day, tilling dropped to every second day, and to less than once a week when the animals were out on pasture full-time.

The carbon-to-nitrogen (N) ratio of the compost was used to gauge when it was ready to spread, with a 12–15:1 ratio hitting the mark. A top-up at this point would possibly see the compost life extend up to two years, reducing replacement costs.

After a year the compost should have enough nutrients to replace one application of N or potassium, and about 25% of annual phosphorus or sulphur fertiliser needs.

Cow health

Cut-and-carry crops have replaced winter cropping on two of the farms, which sees significantly higher feed utilisation by cows and more control over feed intake generally. Better cow health and injury checks are also now possible.

Although body condition scoring was carried out, no pre-mootel scoring was available for comparison. However, farmers were adamant their animals were happier, calmer and less stressed – as were their staff. Having access to the shelters for shade during warmer months and heavy rain events was a big part of this.

Mastitis levels and somatic cell counts remained unchanged with the shelters, although there may potentially be an increased incidence of E. coli mastitis.

Cow deaths were significantly down on all the farms, particularly around calving, and there were fewer metabolic issues.

Modelling woes

The inability to accurately model greenhouse gases (GHGs) following the introduction of these composting structures is a cause for concern.

While modelling suggested N root zone loss over the farm may halve for two of the farms, there was little confidence in results for methane emissions from effluent in the mootels. No modelling was possible for the composting process and potential increase in nitrous oxide emissions.

“More solid research on GHGs in the animal housing context is a crucial factor if we’re moving toward pricing emissions,” says Millar. “This is important so we’re not making gains in one area only to be causing problems in another, and ensures innovative farmers are rewarded for any improvements in emissions management.”

This article was first published in New Ground magazine, issue 4. All text is licensed for re-use under Creative Commons Attribution 4.0 International (CC BY 4.0)

Author

View Our Strategy Document 2019 – 2024

View Our Strategy Document 2019 – 2024

Leave a Reply